Note:

1) This product does not contain a mounting brackets. It compatible Bracket A and Bracket C, please click here to choose and buy.

2) If you need DC power supply for linear actuator, please click here to choose and buy.

Application:

Mainly used for doors, windows, cellars, trapdoors, hatchways, solar tracking system, medical devices, agricultural machinery, vehicles, ships, elevator platforms, lifting tables, TV lifts, robots, cabinetries, massage sofas, electric beds, medical chairs, and other electrical equipment. It can open, close, push, pull, lift, and descend these devices.

It can replace hydraulic and pneumatic products to save power consumption.

Introduction:

This linear actuator has a built-in 10K potentiometer with three output wires connected. When the linear actuator moves, the resistance value between the output lines changes accordingly. In this way, we can obtain the corresponding movement position of the linear actuator by measuring the resistance value.

Feature:

High-quality products and high-quality services

New housing design, high working stability

Metal housing, able to work in very harsh environments

Metal gearbox, high strength wear-resistant gear

Aluminum alloy telescopic tube and outer tube, good corrosion resistant

Heavy duty design, high-power DC motor

With a built-in 10K potentiometer

Advanced waterproof and dustproof technology

Low power consumption and low noise

Built-in two limit switches, linear actuator will automatically stop when stroke rod reaches the limit position.

Automatically lock after stopping, and no power supply is required.

Maintenance-free

Specifications:

Optional working voltage: DC 12V or DC 24V

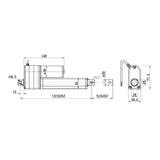

Stroke range: 2 inches or 50 mm

Optional speed: 5±1mm/s, 10±2mm/s, 15±3mm/s, 20±4mm/s, 30±5mm/s, 50±10mm/s, 100±15mm/s

The above is the speed at no load, and the actual working speed will gradually slow down as the load increases.

Max Load capacity: 2000N / 200 Kgs / 450 lbs at 5mm/s

Linear actuator can get maximum load capacity when it operates in the vertical direction, and the pulling force is less than pushing force.

No-load current: 0.5~1A at 12V or 0.3~0.5A at 24V

Full load current: 3~6A at 12V or 1.5~3A at 24V

Please use a 12V/6A or 24V/3A power supply to power a linear actuator or use a 12V/10A or 24V/5A power supply to power two linear actuators, or use a 12V/20A or 24V/10A power supply to power four linear actuators.

Shaft diameter: 20mm

Mounting holes diameter: 6mm

Housing material: Aluminum Alloy

Stroke rod material: Aluminum Alloy

Gear material: Steel Alloy

Motor type: Brushed DC Motor

Built-in potentiometer: 10K ohms

Duty Cycle: 20%, max 5mins continuous use

Cable: Five-core Cable (Two power wires and three potentiometer output wires)

Certifications: CE

Environment temperature: -26℃ to 85℃

Operating noise: about 46dB~56dB (Linear actuators with different parameters will have different noise levels.)

IP rating: IP65

| Different no-load speeds and corresponding maximum thrust: | |||

| No-load Speed | Full load Speed | Maximum Thrust | Self-locking Force |

| 5mm/s | 2.5mm/s | 2000N / 200 kg / 450 lbs | 2200N / 220 kg / 490 lbs |

| 10mm/s | 5mm/s | 1000N / 100 kg / 200 lbs | 1100N / 110 kg / 250 lbs |

| 15mm/s | 7.5mm/s | 800N / 80 kg / 180 lbs | 900N / 90 kg / 200 lbs |

| 20mm/s | 10mm/s | 700N / 70 kg / 160 lbs | 800N / 80 kg / 180 lbs |

| 30mm/s | 15mm/s | 500N / 50 kg / 110 lbs | 600N / 60 kg / 130 lbs |

| 50mm/s | 25mm/s | 300N / 30 kg / 60 lbs | 350N / 35 kg / 80 lbs |

| 100mm/s | 50mm/s | 150N / 15 kg / 30 lbs | 100N / 10 kg / 20 lbs |

Operation:

The electric linear actuator has a five-core cable.

1. The red and black lines are two power lines of the electric linear actuator.

Connect the DC power supply to two power wires of the electric linear actuator. When linear actuator is connected to DC power supply, the stroke rod will extend outward; after switching the power in the reverse direction, the stroke rod will retract inward.

The direction of movement of the stroke rod can be changed by switching the polarity of DC power supply.

2. The white, blue and yellow wires are three output wires of the potentiometer.

The blue and yellow wires are connected to two terminals of the potentiometer, it is a fixed resistance value.

When the linear actuator moves, the resistance value between white wire and yellow wire or white wire and blue wire changes accordingly. In this way, we can obtain the corresponding movement position of the linear actuator by measuring the resistance value. When the linear actuator is extended outwards, the resistance value between white and blue wires will decrease accordingly, and the resistance value between white and yellow wires will increase accordingly. When the linear actuator is retracted inward, the resistance value between white and blue wires will increase accordingly, and the resistance value between white and yellow wires will decrease accordingly.

For example, a linear actuator with a stroke of 200mm and a built-in potentiometer of 10K ohms.

When the linear actuator is fully retracted, the resistance value between white wire and yellow wire is 0.8K ohms, and the resistance value between white wire and blue wire is 9.2K ohms.

When the linear actuator is extended to the 100mm position, the resistance value between white wire and yellow wire is 4.5K ohms, and the resistance value between white wire and blue wire is 5.5K ohms.

When the linear actuator is fully extended, the resistance value between white wire and yellow wire is 9.1K ohms, and the resistance value between white wire and blue wire is 0.8K ohms.

Production time:

The linear actuators are the customized products, and these products are not in stock, we need to spend 3~7 working days to produce them according to the specified parameters in your order.

Return or Exchange:

The Linear Actuators are the customized products, we need to produce them according to the specified parameters in your order, so that we do not accept returns or cancel orders. If customers order unsuitable linear actuators themselves, we also do not accept exchanges, please understand.